New higher temperature limit!

DESCRIPTION

ICA H-Block is a 18# density molded fiberglass which is brown in color. H-Block was designed to be utilized as a superior pipe support system and to prevent crushing and bottoming-out of the surrounding insulation. H-Block enhances the thermal and vibration control properties of the entire insulation system.

APPLICATION

ICA H-Block is designed for all types of piping systems operating at temperatures between -120° F. to +1000° F. H-Block sizes will accommodate pipe sizes from 1/2" to 24" IPS, and insulation thicknesses from 1/2" to 4". For higher insulation thicknesses or other specialized sizes or applications, please contact ICA or your local distributor.

ADVANTAGES

ICA H-Block is available in a wide range of standard sizes. These basic sizes have been chosen to help you plan and install pipe support insulation for many types and sizes of piping systems. Because H-Block is continuously produced and stocked in these sizes, you can forget about ordering problems, long manufacturing lead times, and tying-up valuable inventory space.

In the field, H-Block is easy to handle and simple to install. ICA H-Block is superior to a wood block application. It is incombustible; and immune to rot, corrosion, odors, insects, and oxidation. H-Block resists aging and thermal shock, and its compressive strength is unaffected by water, oils, gasoline, or common solvents. |

Physical Properties:

Service temperatures:

-120° F. to +1000° F.

Density:

18 lb. cu./ft.

Moisture absorption:

0.2% by volume, 96 hrs. at 120° F. 96% RH

Corrosion:

Does not cause or accelerate corrosion

Safety:

Non-combustible

Shrinkage:

None

Dimensionally stable

Alkalinity:

Ph9

Thermal Conductivity:

K = .30 (stable, non-deteriorating)

Compressive strength:

nominal 5% deflection at 30PSI

nominal 10% deflection at 80PSI

ASTM E84 25/50:

10 flame spread index,

10 smoke development |

|

ICA H-BLOCK CUSTOMERS

The ICA H-Block is a 18# density fiberglass pipe support with widths of 1", 1 1/2", 2", 2 1/2" and 3". The block lengths are 6", 9", 12" and 14". When calculated and installed correctly, they provide adequate support and prevent crushing of the surrounding pipe insulation. The saddles being used must be long enough to provide full support of the blocks.

The following chart demonstrated how to figure the load factor of the blocks as described on the H-Block Technical Data Sheet. If your calculations fall within these conditions, the blocks will provide adequate support for your system.

| Pipe Size |

Width of Block

A |

Length of Hanger & Block

B |

Block Required

C |

Max Support at 5% deflection formula: AxBxCx30PSI |

Max Support at 10% deflection formula: AxBxCx80PSI |

| Up to 5" |

1 1/2"

1 1/2"

1 1/2" |

12"

18"

24" |

1

1

1 |

540#

810#

1080#

|

1440#

2160#

2880#

|

| 6" to 8" |

1 1/2"

1 1/2"

1 1/2" |

12"

18"

24" |

2

2

2

|

1080#

1620#

2160# |

2880#

4320#

5760# |

| 10" to 12" |

1 1/2"

1 1/2"

1 1/2" |

12"

18"

24" |

3

3

3 |

1620#

2430#

3240# |

4320#

6480#

8640# |

| 14" to 16" |

1 1/2"

1 1/2"

1 1/2" |

12"

18"

24" |

4

4

4

|

2160#

3240#

4320# |

5760#

8640#

11520# |

| 18" to 24" |

1 1/2"

1 1/2"

1 1/2" |

12"

18"

24" |

5

5

5

|

2700#

4050#

5400# |

7200#

10800#

14400# |

Custom Molders of Thermal Acoustical Insulation

"Our unique molding process makes us different & better."

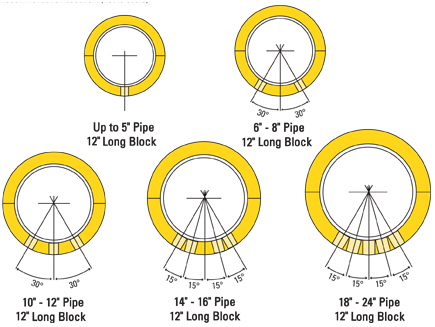

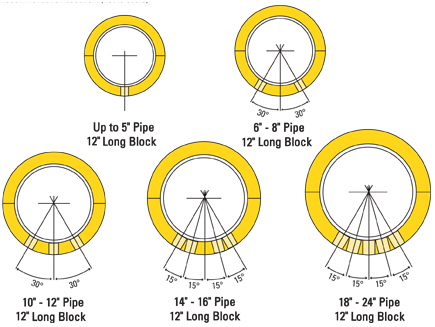

H-Block Recommendation Location: (not to scale)

INSTALLATION

ICA H-Block is placed between the bottom of the pipe to be supported and the metal shield. On pipe sizes above 5" IPS, H-Block should be oriented along the bottom 60° arc of the system. The thickness of the H-Block should be the same thickness as the insulation system. H-Block can be applied with minimum effort and simple tools by removing a "block section" from the pipe insulation, then replacing this section with a heavy density H-Block. Each H-Block is marked to identify which side is placed against the pipe. |